TGL (GF) Couplings, Cov Couplings Iav Nkaus Nrog Daj Nylon Tes Tsho

Cov iav txuas nkhaus

TGL Series (GF-SERIES)

Cov yam ntxwv ntawm cov khoom

• Ob chav seem nkhaus nto coupling

• Siv dav hauv ntau yam teb ntawm cov tshuab thiab hydraulics

• Tsis yog kev saib xyuas ntawm cov khoom siv nylon thiab hlau

• Kev them nyiaj rau qhov yuam kev axial, radial thiab angular

• Lub rooj sib dhos ntxig axial yooj yim heev

• Qhov kam rau ntawm qhov khoom yog H7 raws li Io tus qauv ISO, thiab qhov kam rau ntawm qhov dav ntawm qhov tseem ceeb yog raws li tus qauv, DIN6885 / 1byJS9, Lwm nti thiab lub qhov cone

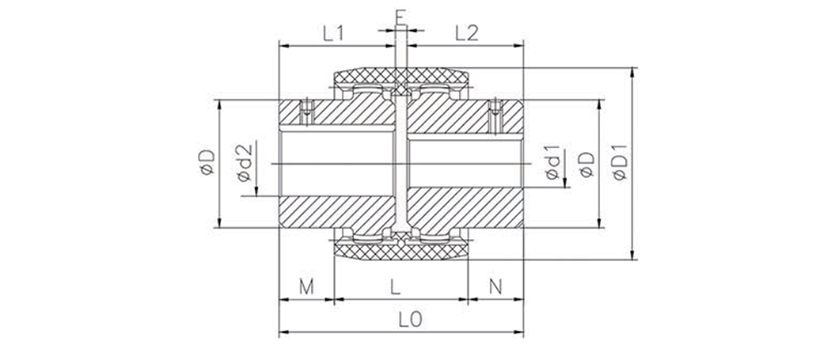

• Yog xav paub qhov loj ntawm kev teeb tsa, saib daim ntawv hauv qab no:

| Qauv | Qhov tho tiav lawm dl, d2 ){%XYQC.png) | Qhov Loj (hli) | Qhov hnyav ntawm kev sib txuas nrog Max, Aperture | RatedTorque | |||||||||||

| Dav Dav | Ntev dua | Premachlned Qhov tho qhov |

| Max, qhov qhib | L1, L2 | L0 | L | M,N | E | L1, L2 Siab Tshaj | D1 | D | Qhov hnyav ntawm Nylon-seelve | Qhov Hnyav Tag Nrho | Nm |

| TGL-14 | TGL-14-L | - | Cov neeg muas zaub tuaj yeem xaj tiav lawm | 14 | 23 | 50 | 37 | 6.5 | 4 | 40 | 40 | 24 | 0.02 | 0.14 | 10 |

| TGL-19 | TGL-19-L | - | 19 | 25 | 54 | 37 | 8.5 | 4 | 40 | 48 | 30 | 0.03 | 0.21 | 16 | |

| TGL-24 | TGL-24-L | - | 24 | 26 | 56 | 41 | 7.5 | 4 | 50 | 52 | 36 | 0.04 | 0.25 | 20 | |

| TGL-28 | TGL-28-L | - | 28 | 40 | 84 | 46 | 19 | 4 | 55 | 66 | 44 | 0.07 | 0.62 | 45 | |

| TGL-32 | TGL-32-L | - | 32 | 40 | 84 | 48 | 18 | 4 | 55 | 76 | 50 | 0.09 | 0.83 | 60 | |

| TGL-38 | TGL-38-L | - | 38 | 40 | 84 | 48 | 18 | 4 | 60 | 83 | 58 | 0J1 | 1.04 | 80 | |

| TGL-42 | TGL-42-L | - | 42 | 42 | 88 | 50 | 19 | 4 | 60 | 92 | 65 | 0.14 | 1.41 | 100 | |

| TGL-48 | TGL-48-L | - | 48 | 50 | 104 | 50 | 27 | 4 | 60 | 92 | 67 | 0.16 | 1.43 | 140 | |

| TGL-55 | TGL-55-L | - | 55 | 52 | 108 | 58 | 25 | 4 | 65 | 114 | 82 | 0.26 | 2.50 | 240 | |

| TGL-65 | TGL-65-L | - | 65 | 55 | 114 | 68 | 23 | 4 | 70 | 132 | 95 | 0.39 | 3.58 | 380 | |

Lub GF Coupling muaj ob lub hub hlau nrog cov hniav iav sab nraud uas muaj crowned thiab barrelled, Oxidation blacked tiv thaiv, txuas nrog los ntawm lub tes tsho resin hluavtaws. Lub lub tes tsho yog tsim los ntawm cov polyamide hnyav molecular siab, thermally conditioned thiab impregnated nrog cov roj nplua nyeem khov kho kom muab lub neej ntev uas tsis tas yuav saib xyuas. Lub tes tsho no muaj kev tiv taus siab rau qhov av noo ntawm huab cua thiab qhov kub ua haujlwm ntawm -20˚C txog +80˚C nrog lub peev xwm tiv taus 120˚C rau lub sijhawm luv luv.

Cov GF Series Couplings yog ua los ntawm ob lub hub ntev; ib lub hub txheem uas haum rau feem ntau daim ntawv thov, thiab lub hub ntev dua.