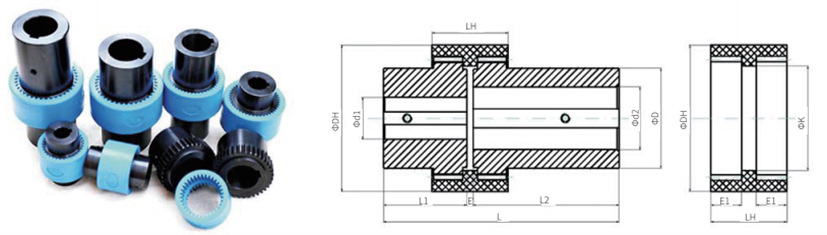

NL Hom Hniav Elastic Couplings nrog Nylon Tes Tsho

NL hom hniav elastic coupling

• Siv tau yooj yim, kho Io yooj yim, buffer vibration;

• Kev hloov pauv loj axial, micro radial displacement thiab angular displace uas them taus;

• Nws yog qhov tsim nyog los hloov ntau qhov kev hloov pauv rov qab thiab pib lub qag ceev ceev.

| Hom | DH | LH | D | dl, Tus nqi siab tshaj plaws | d2, Tus nqi siab tshaj plaws | E | K | Tus naj npawb ntawm cov hniav | Modulus | Lub zog siab tshaj plaws ntawm lub cev muaj zog (KW) | N/m Nominal torque Nm |

| NL1 | 40 | 40 | 26 | 16 | 25 | 5 | 27 | 20 32 | 1.5 1 | 0.75 | 40 |

| NL2 | 57 | 35 | 36 | 二 | 50 | 6 | 39 | 28 48 | 1.5 1 | 1.1 | 100 |

| NL3 | 68 | 45 | JL | 23 | 6 | 46 | 25 34 | 2 1.5 | 4 | 160 | |

| NL4 | 82 | 47 | 58 | 38 | 80 | 8 | 61 | 32 45 | 2 1.5 | 7.5 | 250 |

| NL5 | 93 | 50 | 68 | 42 | 110 | 10 | 70 | 36 38 | 2 2 | 15 | 315 |

| NL6 | 102 | 52 | 70 | 48 | 110 | 12 | 77 | 40 32 41 | 2 2.5 2 | 22 | 400 |

| NL7 | 116 | 60 | 80 | 55 | 110 | 11 | 84 | 36 42 45 | 2.5 2 2 | 30 | 630 |

| NL8 | 140 | 72 | 96 | 65 | 140 | 11 | 101 | 36 42 45 31 | 3 2.5 2.5 3 | 55 | 1250 |

| 大NL9 | 175 | 93 | 124 | 80 | 170 | 16 | 129 | 45 46 | 3 3 | 90 | 2000 xyoo |

| NL10 | 220 | 80 | 157 | 95 | 170 | 19 | 167 | 44 | 4 | 180 | 3150 |

| Kev piav qhia txog kev txiav txim | Lub Npe | Hom | Lub qhov sab hauv Φ d1 * Axial ntev I1 / Lub qhov sab hauv Φ d1 * Axial ntev l2 | ||||||||

| Kev sib txuas | ML3 | Φ25 * 40Φ28 * 60 | |||||||||

NL hniav coupling nylon tes tsho

NL coupling yog cov khoom tshiab tshaj plaws hauv Suav teb, nws tau siv dav hauv tsev thiab txawv teb chaws.

Cov khoom no yog tsim los ntawm Ji nan Institute of foundry thiab forging machinery, thiab nws yog tsim rau inter axle thiab flexible transmission. Jt tso cai rau axial radial displacement loj dua thiab angular displacement, thiab muaj qhov zoo ntawm cov qauv yooj yim, yooj yim txij nkawm, yooj yim disassembly thiab sib dhos, suab qis, me ntsis poob ntawm kev sib kis efficiency thiab lub neej ntev. Nws tau txais tos los ntawm cov neeg siv.

Yuav kom ua tau raws li txhua yam kev kho dua tshiab thiab kev xaiv khoom siv thiab cov khoom siv seem, peb lub Hoobkas tuaj yeem muab txhua yam kev sib txuas hniav sab hauv nrog ntau yam kev qhia tshwj xeeb, thiab lees txais cov xaj tsis yog tus qauv raws li cov neeg siv xav tau.

NL hniav txuas nylon tes tsho khoom catalog

| Lub Npe | Qauv | Tus naj npawb ntawm cov hniav | Modulus |

| Lub tsho nylon | NL1 | 32/30 | 1/1.5 |

| Lub tsho nylon | NL2 | 42/28 | 1/1.5 |

| Lub tsho nylon | NL3 | 25/34 | 2/1.5 |

| Lub tsho nylon | NL4 | 32/45 | 2/1.5 |

| Lub tsho nylon | NL5 | 36/38 | 2 |

| Lub tsho nylon | NL6 | 32/40 | 2.5/2 |

| Lub tsho nylon | NL7 | 45/36 | 2/2.5 |

| Lub tsho nylon | NL8 | 31/36/42/45 | 3/2.5 |

| Lub tsho nylon | NL9 | 4 5/4 6 | 3 |

| Lub tsho nylon | NL10 | 44 | 4 |

NL Cov Khoom Siv Sib Txuas / Cov Khoom Siv Sib Txuas:

1. Ib Daim hlau nplaum sib txuas ua ke.

2. Tsis muaj kev tawm tsam.

3. Kev nqus ntawm qhov sib luag, qhov sib txawv ntawm lub kaum sab xis thiab qhov kawg ntawm lub ncej los ntawm cov khoom siv elastic.

4. Cov yam ntxwv sib hloov clockwise thiab anticlockwise zoo sib xws

5. Hom ntsia hlau los yog Hom Clamp.

6. Khoom siv: C45 cov ntaub ntawv, lub cev muaj zog, lossis ib tus neeg siv khoom thov.

7. Tiv thaiv kev xeb, siv dav hauv kev kho mob, chemistry.

8. Kev yooj ywm siab.

9. Rau servomotor stepmotor.

10. Qhov ntev uas xaiv tau raws li tus neeg siv khoom lub hom phiaj.